Postion: Home > Our Case > Heat Sink Manufacturing >

CATEGORIES

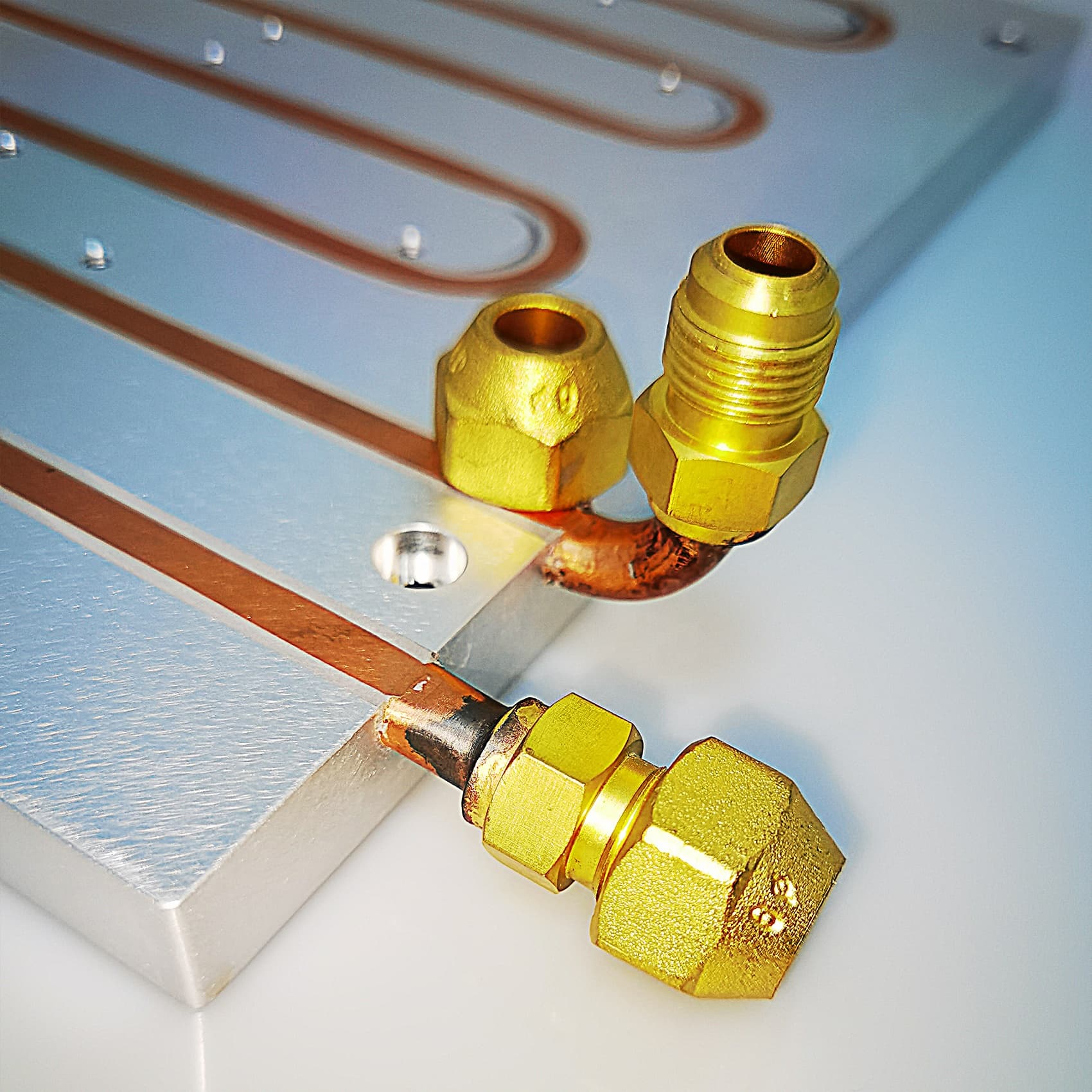

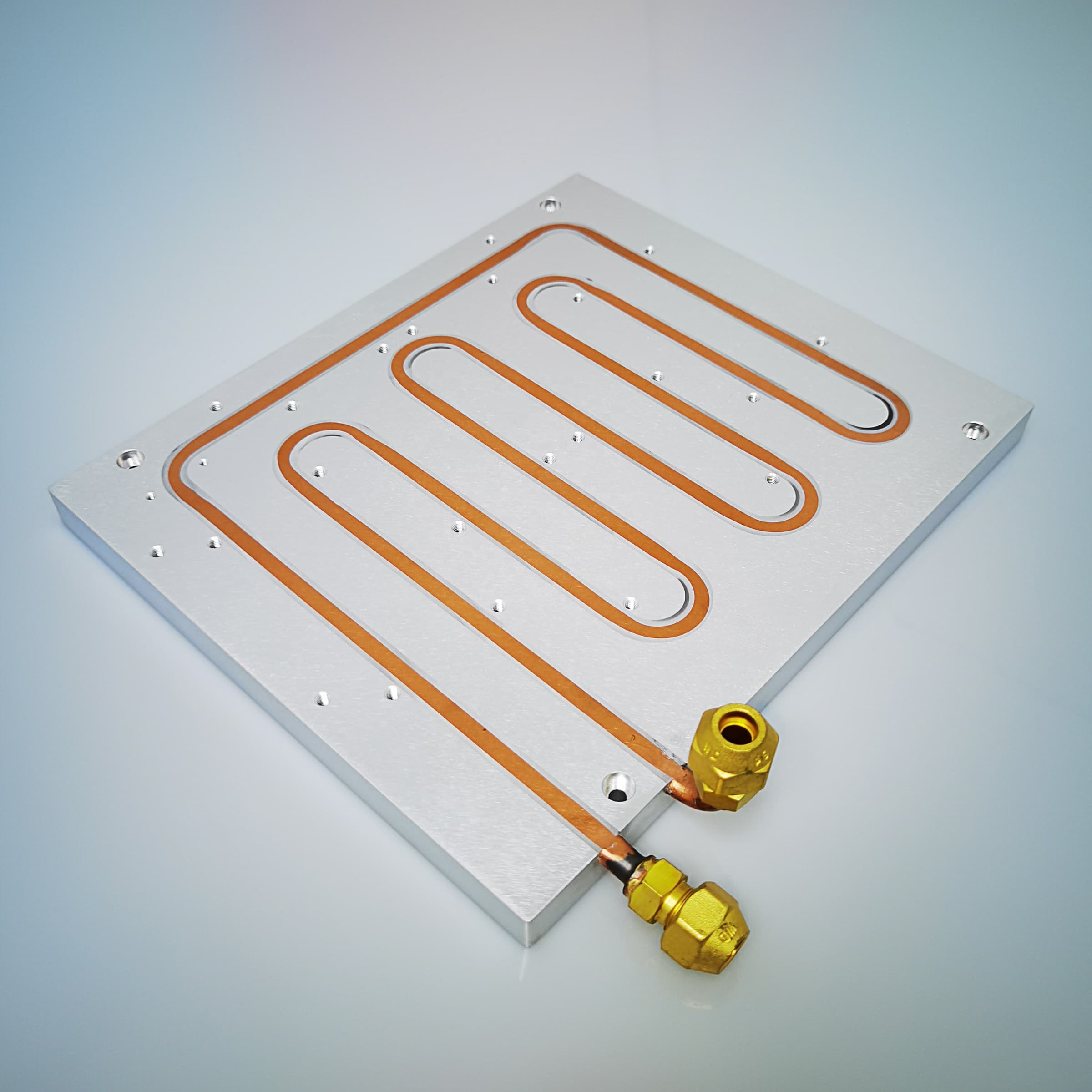

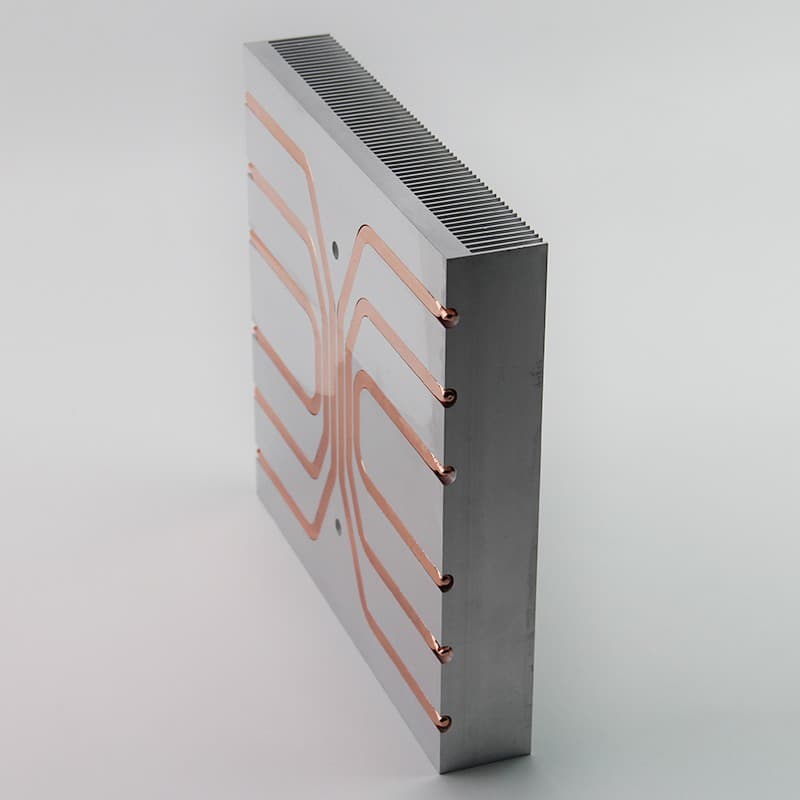

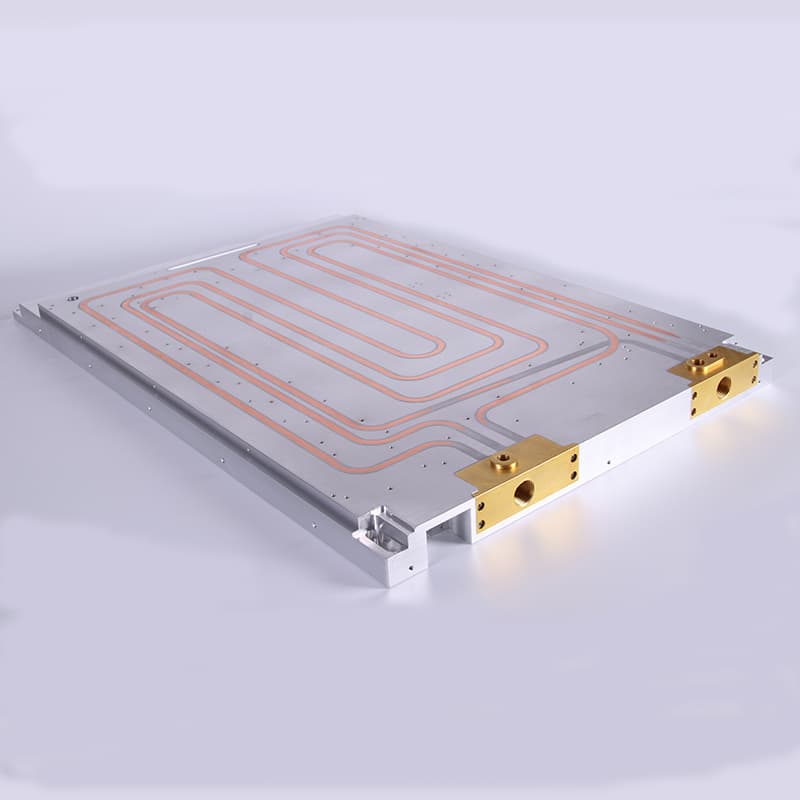

CATEGORIESNeed reliable cooling for your high-power devices? Our factory specializes in manufacturing buried copper tube cold plates with precise channel routing, leak-proof sealing, and customized connector options—designed for thermal-critical systems like EV batteries, power modules, and communication equipment.

We integrate high-purity copper tubes into machined aluminum plates, offering fast heat exchange and structural stability. From prototypes to large-volume orders, we deliver performance and consistency trusted by global OEM clients.

→ High thermal conductivity from embedded copper tubes

→ CNC-machined aluminum base for structural strength

→ Custom inlet/outlet design, pressure-tested for leaks

→ Vacuum brazing, epoxy bonding, or TIG welded per project need

→ EV battery thermal management

→ Power inverter and IGBT module cooling

→ LED and laser equipment

→ Telecom base stations and RF devices

We provide design-for-manufacturing feedback, pressure testing, custom connector welding, and fast prototyping—ensuring your cooling system runs safely and efficiently.

You benefit from:

→ Technical drawing evaluation and optimization

→ Reliable delivery schedule and global shipping

→ ISO-based quality control and 100% testing

→ One-on-one communication with our engineers

Want to upgrade your thermal system with a high-performance cold plate?

E-MAIL: info@hms1688.com

Share your drawings or application details—we’ll reply within 24 hours!

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | precision cnc machining and milling services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Sheet Metal Enclosure Fabrication | Surface Finishing |