Postion: Home > Our Case > Heat Sink Manufacturing >

CATEGORIES

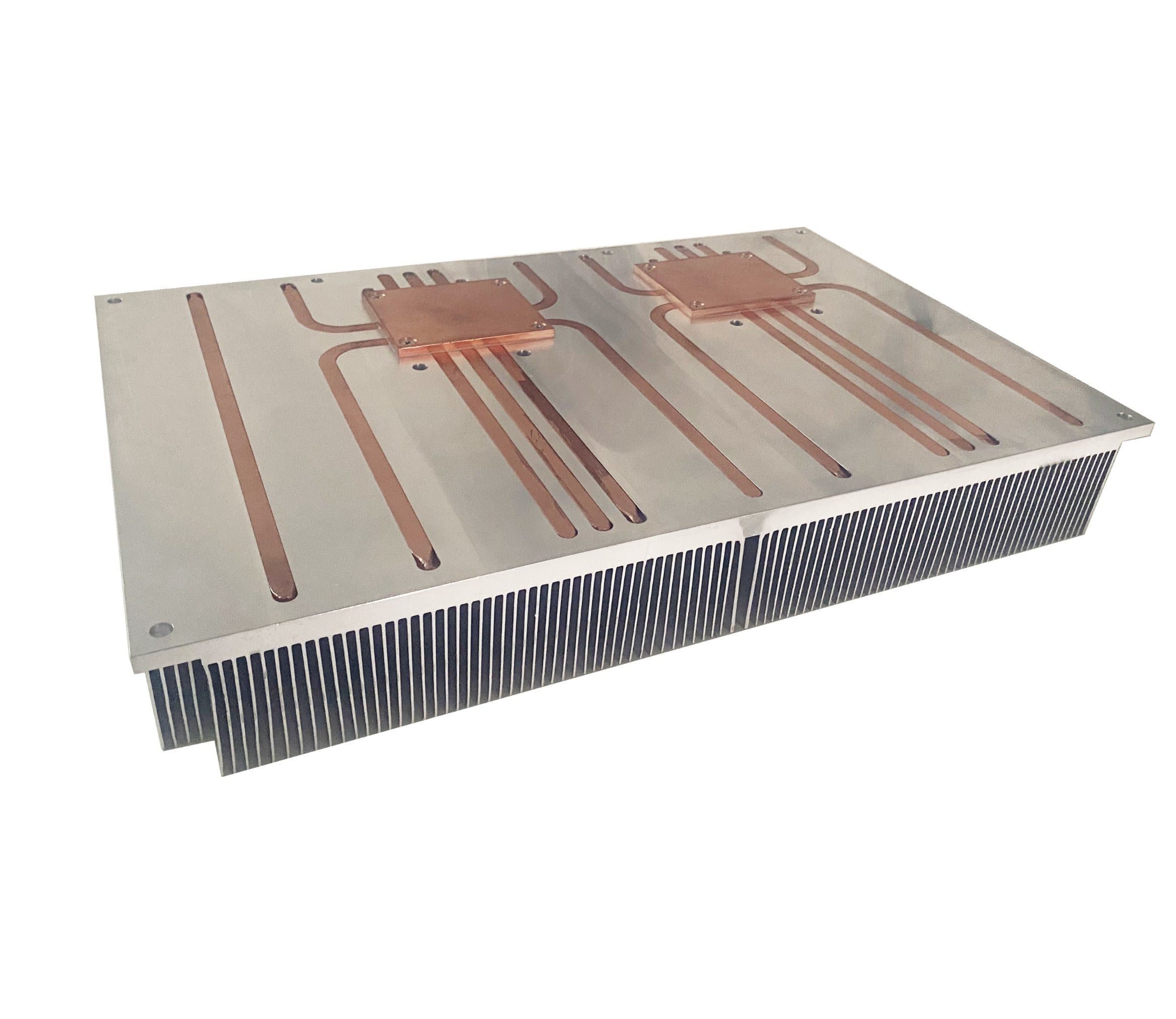

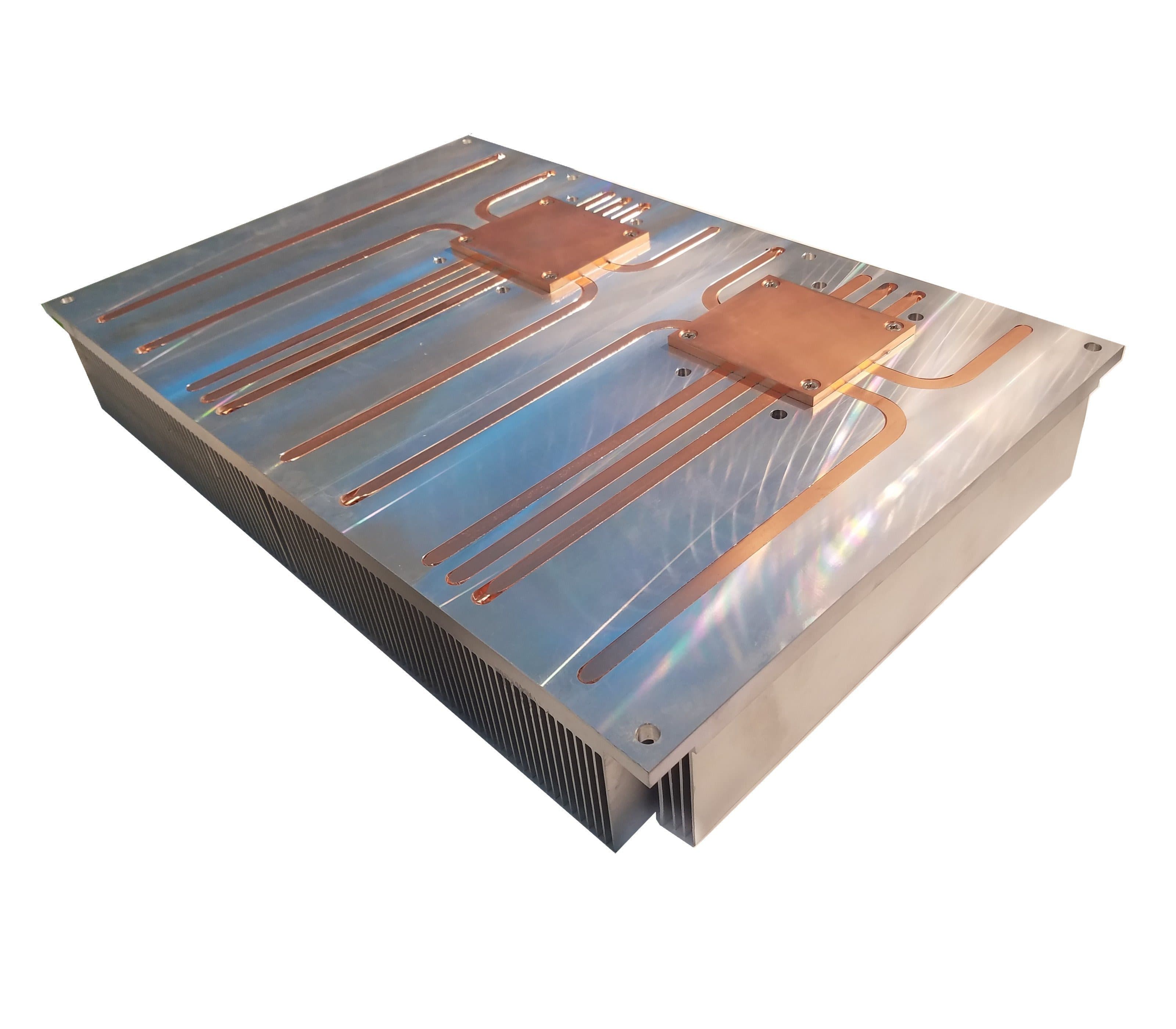

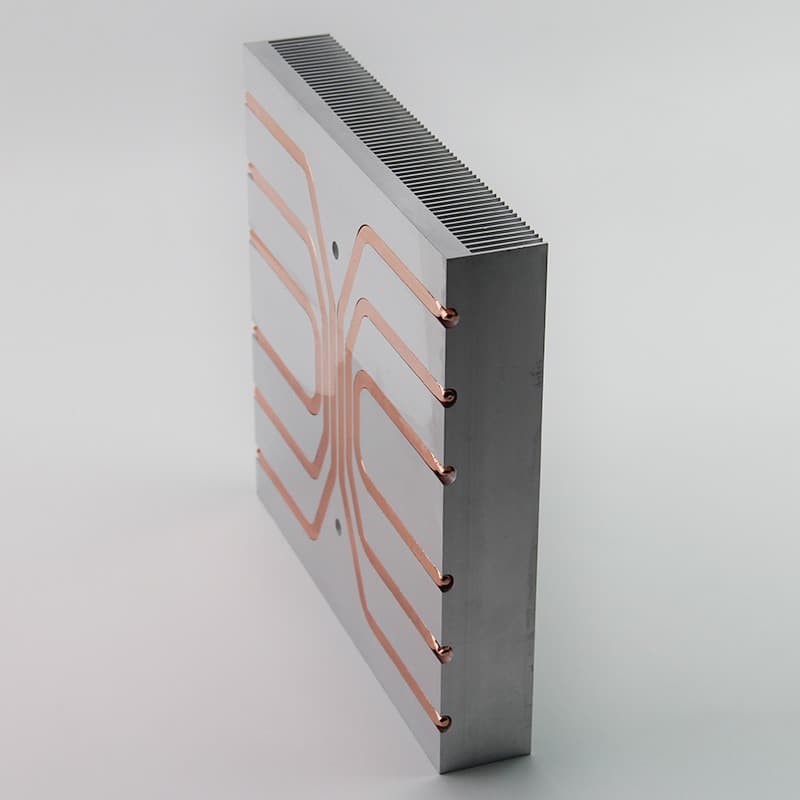

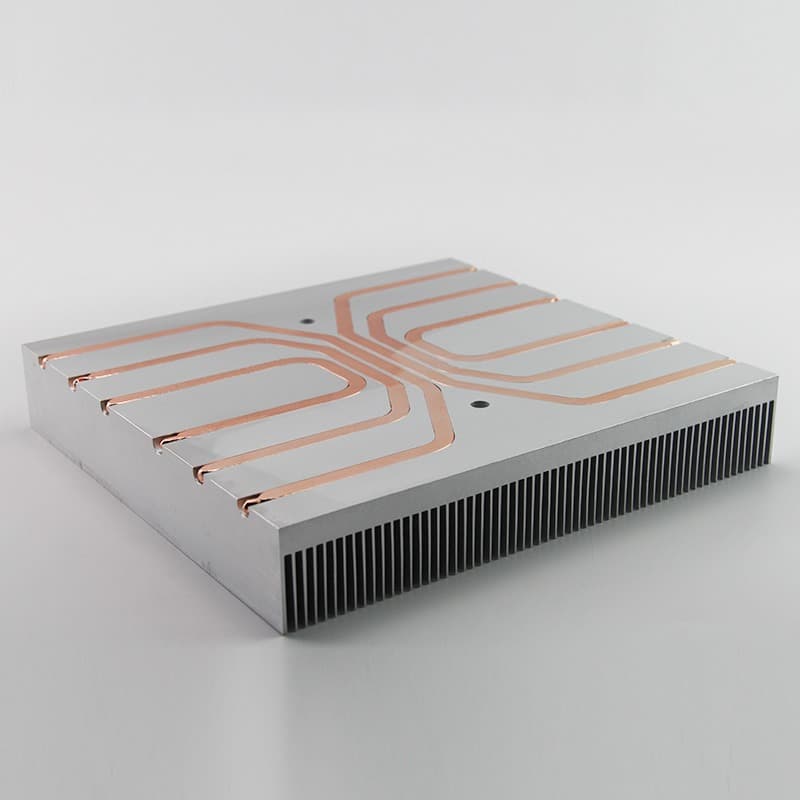

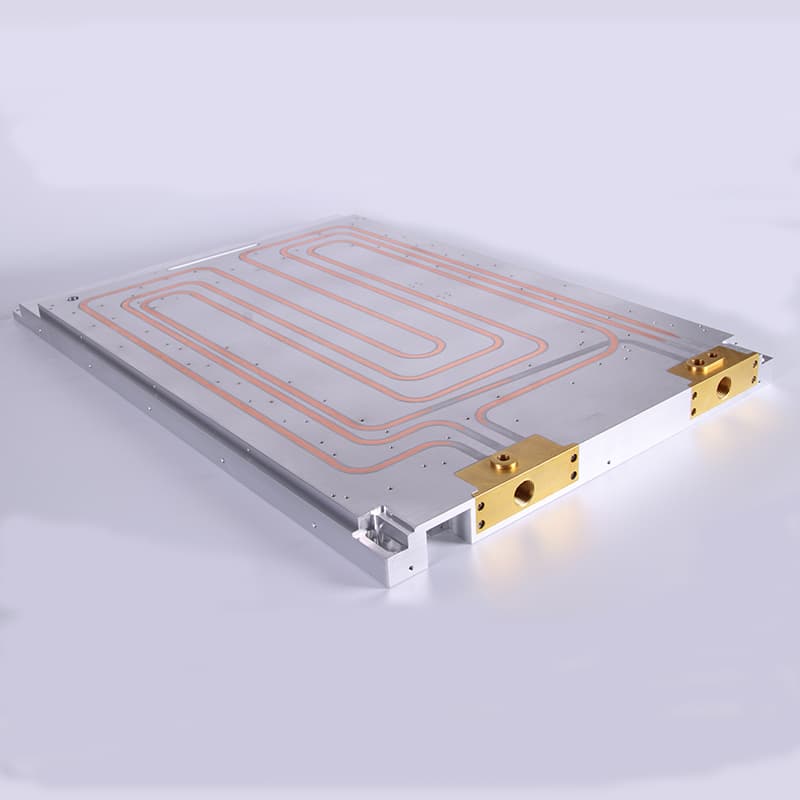

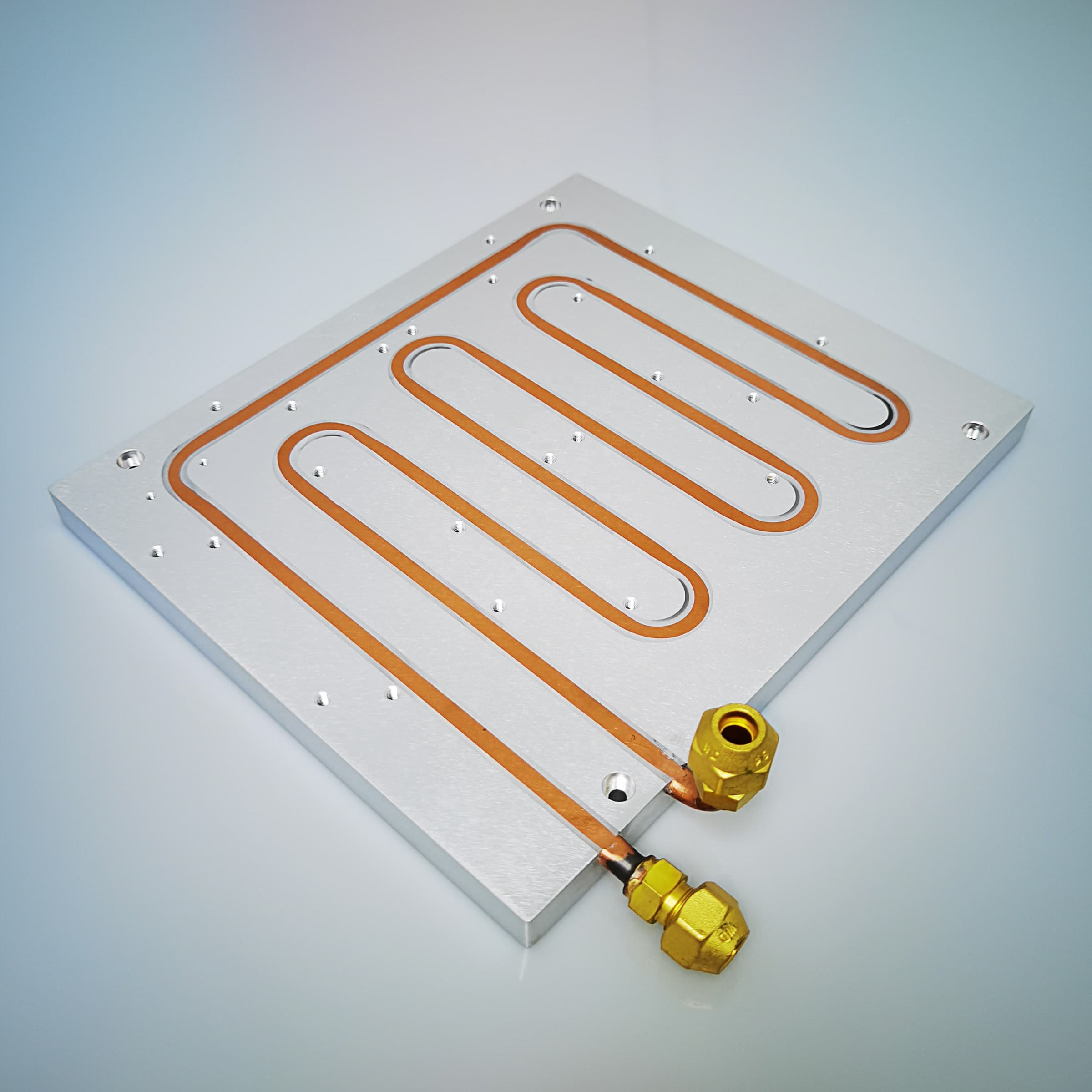

CATEGORIESStruggling with heat issues in high-performance devices? Our factory delivers custom heat sinks and liquid cold plates engineered for demanding industrial, power, and electronic applications. Whether you require heat pipe integration, vacuum brazing, or high-density fin structures, we turn your drawings into high-efficiency thermal components with fast lead times and stable quality.

With 10+ years of experience serving global OEM clients, we help reduce overheating risks and improve product reliability—one thermal solution at a time.

→ High-Efficiency Fin Design: Optimized airflow and heat dispersion for superior cooling performance.

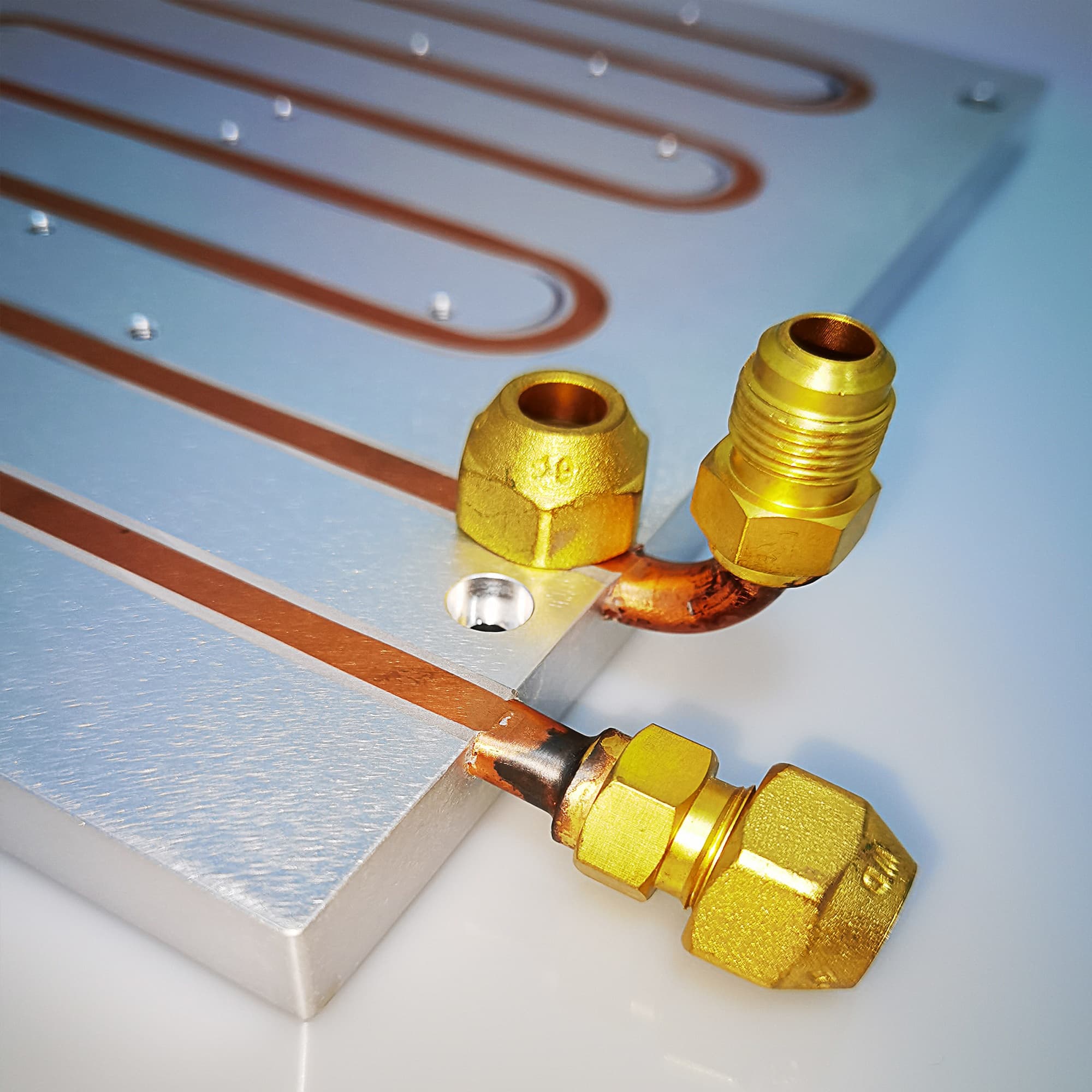

→ Aluminum-Copper Hybrid: Achieve the perfect balance of conductivity and manufacturing cost.

→ Flexible Custom Layouts: Heat pipe and tube routing tailored to your enclosure or PCB shape.

→ Secure Joining Techniques: Vacuum brazing, soldering, and bonding ensure long-term reliability under tough conditions.

→ High-power semiconductors (IGBTs, MOSFETs, power modules)

→ 5G telecom stations and industrial routers

→ Laser diode and LED system cooling

→ EV battery thermal management and storage modules

From early-stage prototyping to full-scale manufacturing, we provide complete engineering support including thermal simulation, CNC machining, custom fixture design, and pressure testing.

Our clients benefit from:

→ Quick response & engineering feedback

→ Competitive pricing direct from the factory

→ Fast sample delivery (7–12 days typical)

→ Strict ISO-based quality control

Want to reduce project lead time and cooling risks?

E-MAIL: info@hms1688.com

Send your drawings or technical requirements — we’ll reply within 24 hours!

Prev: No document!

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | precision cnc machining and milling services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Sheet Metal Enclosure Fabrication | Surface Finishing |