Postion: Home > Our Case > Metal Fabrication >

CATEGORIES

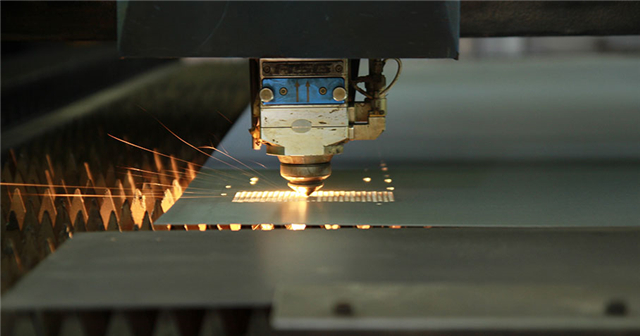

CATEGORIESAt Hongming Sheng, we offer professional sheet metal laser cutting services using advanced CNC equipment and precision processes. Whether you require intricate components or large-scale production, our laser cutting solutions ensure clean edges, minimal distortion, and high repeatability.

We produce various precision laser-cut metal parts including battery boxes, brackets, control panels, electronic shells, and more.

We also offer full-service chassis and cabinet fabrication, including cutting, punching, bending, welding, and finishing. We handle thicknesses from 0.1mm to over 10mm, perfect for electronic enclosures, printer frames, gaming cabinets, and telecom cases.

Recommended thickness for cabinet parts: 1.0 / 1.2 / 1.5 / 2.0 / 2.5 / 3.0 mm

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | precision cnc machining and milling services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Sheet Metal Enclosure Fabrication | Surface Finishing |