Postion: Home > Our Case > Metal Fabrication >

CATEGORIES

CATEGORIES

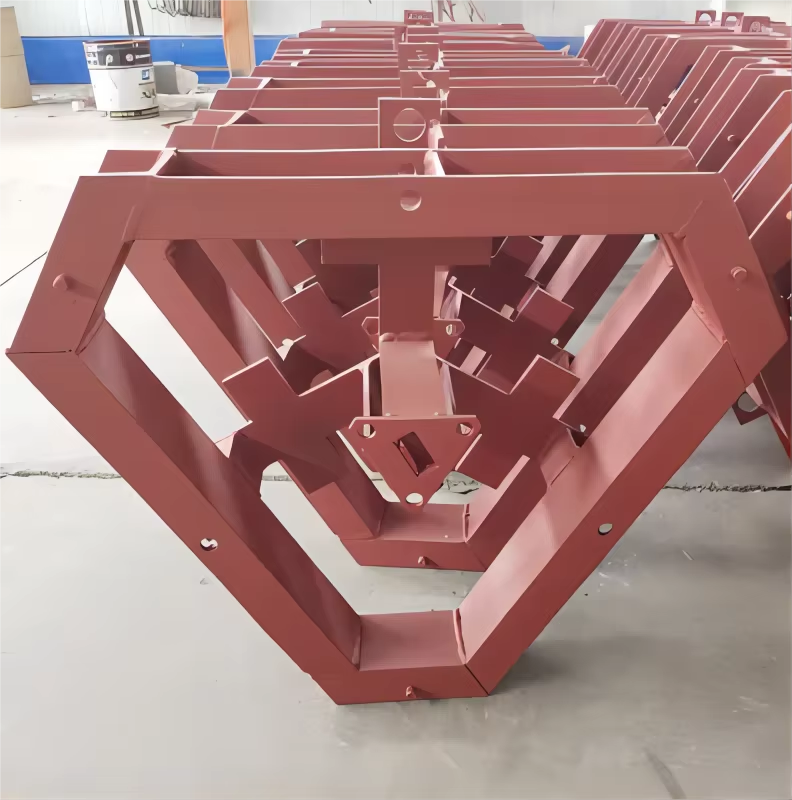

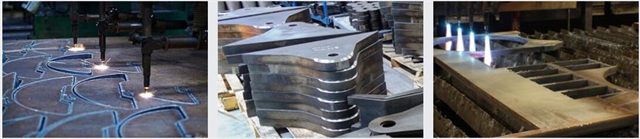

Looking for high-precision sheet metal prototype fabrication? Our factory provides fast turnaround and full-process support—from drawing to delivery. Whether you need functional prototypes or small-batch samples, we deliver with speed, accuracy, and quality.

Our engineering team integrates laser cutting, CNC machining, welding, stamping and surface finishing to help you validate design feasibility and accelerate product development cycles.

E-MAIL: info@hms1688.com

Sheet metal prototyping is the process of producing sample parts to test shape, function, and manufacturability before mass production. It helps reduce design risks and gain investor or customer approval faster.

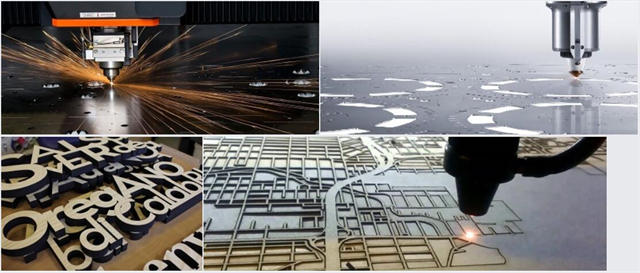

Clean cuts and tight tolerances (±0.15mm) ideal for fine-featured prototypes.

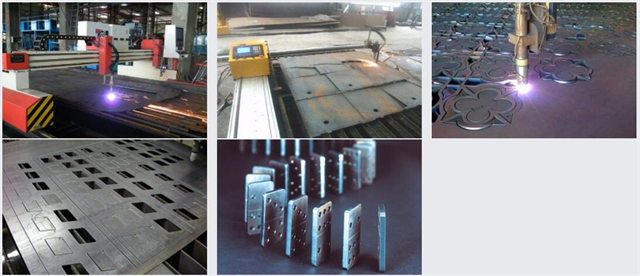

Cold cutting for distortion-free, high-integrity parts.

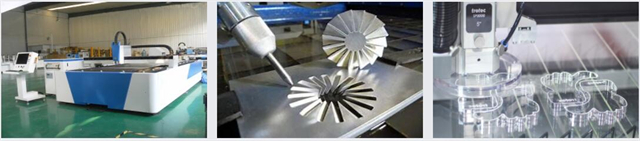

Efficient for high-consistency brackets, enclosures, clips, and covers.

3-, 4-, and 5-axis CNC for metal or plastic prototype parts with precision fit and finish.

Ideal for thin, intricate patterns at lower cost and faster lead time.

MIG, TIG, laser and arc welding available for fast and strong joins.

Smoothing edges, removing burrs, preparing surfaces for coatings or cosmetic review.

We offer anodizing, powder coating, painting, polishing, and custom textures for final looks and protection.

Send your drawings now—our team will respond with feedback and pricing within 12 hours. Partner with a factory trusted for prototypes that look and perform like production parts.

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | precision cnc machining and milling services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Sheet Metal Enclosure Fabrication | Surface Finishing |