Postion: Home > Our Case > Stamping & Bending >

CATEGORIES

CATEGORIESLooking for a fast, cost-effective, and precise partner for your stamped or fabricated metal components? At Hongming Sheng, we provide high-volume and prototype sheet metal stamping solutions with in-house tooling design and full-scale production capabilities. Our services support industries such as automotive, electronics, medical, telecom, and consumer goods.

With 15+ years of expertise and clients in 30+ countries, we deliver tooling, stamping, deep drawing, secondary processing, and full assembly services — all under one roof.

E-MAIL: info@hms1688.com

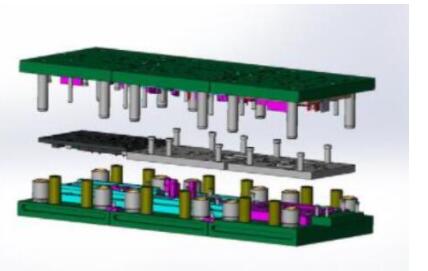

We build stamping dies in-house using SolidWorks and CAD/CAM software. Our tooling engineers handle everything from design to EDM machining and assembly.

In-house tooling ensures better quality control, lower lead time, and excellent part repeatability across large volumes.

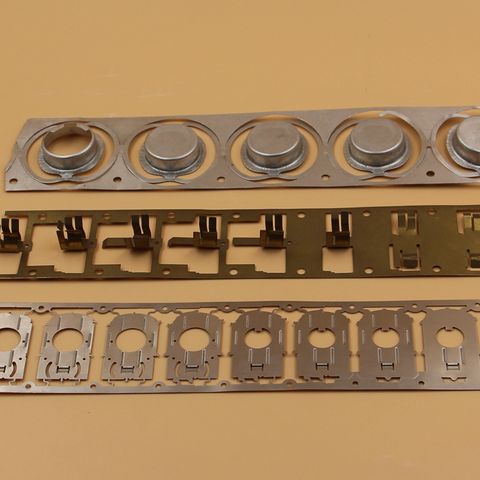

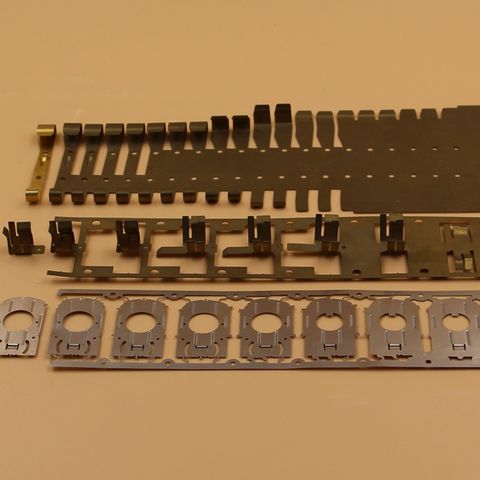

Processes include blanking, punching, coining, flanging, and bending. Suitable for high-speed, high-precision parts.

Ideal for producing hollow, cylindrical parts with consistent wall thickness — available for steel, stainless, and aluminum.

Multi-step stamping using progressive dies for complex parts. Perfect for mid- to high-volume production requiring high efficiency.

Need help with drawings or project consulting?

Contact our team now or email info@hms1688.com

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | precision cnc machining and milling services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Sheet Metal Enclosure Fabrication | Surface Finishing |